Merchant Shipping Act, 1951 (Act No. 57 of 1951)SchedulesSecond ScheduleProtocol of 1978 Relating to the International Convention for the Safety of Life at Sea, 1974AnnexChapter II–1 : Construction — Subdivision and Stability, Machinery and Electrical InstallationsPart B — Subdivision and StabilityRegulation 18 : Bilge pumping arrangements in passenger ships |

| (a) | Ships shall be provided with an efficient bilge plant capable of pumping from and draining any watertight compartment which is neither a permanent oil compartment nor a permanent water compartment under all practicable conditions after a casualty whether the ship is upright or listed. For this purpose wing suctions will generally be necessary except in narrow compartments at the ends of the ship, where one suction may be sufficient. In compartments of unusual form, additional suctions may be required. Arrangements shall be made whereby water in the compartment may find its way to the suction pipes. Where in relation to particular compartments the Administration is satisfied that the provision of drainage may be undesirable, it may allow such provision to be dispensed with if calculations made in accordance with the conditions laid down in paragraph (b) of Regulation 7 of this Chapter show that the safety of the ship will not be impaired. Efficient means shall be provided for draining water from insulated holds. |

(b)

| (i) | Ships shall have at least three power pumps connected to the bilge main, one of which may be attached to the propelling unit. Where the criterion numeral is 30 or more, one additional independent power pump shall be provided. |

| (ii) | The requirements are summarized in the following table: |

Criterion numeral |

Less than 30 |

30 and over |

Main engine (may be replaced by one independent pump). |

1 |

1 |

Independent pumps. |

2 |

3 |

| (iii) | Sanitary, ballast and general service pumps may be accepted as independent power bilge pumps if fitted with the necessary connections to the bilge pumping system. |

| (c) | Where practicable, the power bilge pumps shall be placed in separate watertight compartments so arranged or situated that these compartments will not readily be flooded by the same damage. If the engines and boilers are in two or more watertight compartments, the pumps available for bilge service shall be distributed throughout these compartments as far as is possible. |

| (d) | On ships 91,5 metres (300 feet) or more in length or having a criterion numeral of 30 or more, the arrangements shall be such that at least one power pump shall be available for use in all ordinary circumstances in which a ship may be flooded at sea. This requirement will be satisfied if— |

| (i) | one of the required pumps is an emergency pump of a reliable submersible type having a source of power situated above the bulkhead deck; or |

| (ii) | the pumps and their sources of power are so disposed throughout the length of the ship that under any condition of flooding which the ship is required to withstand, at least one pump in an undamaged compartment will be available. |

| (e) | With the exception of additional pumps which may be provided for peak compartments only, each required bilge pump shall be arranged to draw water from any space required to be drained by paragraph (a) of this Regulation. |

(f)

| (i) | Each power bilge pump shall be capable of giving a speed of water through the required main bilge pipe of not less than 122 metres (400 feet) per minute. Independent power bilge pumps situated in machinery spaces shall have direct suctions from these spaces, except that not more than two such suctions shall be required in any one space. Where two or more such suctions are provided there shall be at least one on the port side and one on the starboard side. The Administration may require independent power bilge pumps situated in other spaces to have separate direct suctions. Direct suctions shall be suitably arranged and those in a machinery space shall be of a diameter not less than that required for the bilge main. |

| (ii) | In coal-burning ships there shall be provided in the stokehold, in addition to the other suctions required by this Regulation, a flexible suction hose of suitable diameter and sufficient length, capable of being connected to the suction side of an independent power pump. |

(g)

| (i) | In addition to the direct bilge suction or suctions required by paragraph ( f ) of this Regulation there shall be in the machinery space a direct suction from the main circulating pump leading to the drainage level of the machinery space and fitted with a non-return valve. The diameter of this direct suction pipe shall be at least two-thirds of the diameter of the pump inlet in the case of steamships, and of the same diameter as the pump inlet in the case of motorships. |

| (ii) | Where in the opinion of the Administration the main circulating pump is not suitable for this purpose, a direct emergency bilge suction shall be led from the largest available independent power driven pump to the drainage level of the machinery space; the suction shall be of the same diameter as the main inlet of the pump used. The capacity of the pump so connected shall exceed that of a required bilge pump by an amount satisfactory to the Administration. |

| (iii) | The spindles of the sea inlet and direct suction valves shall extend well above the engine room platform. |

| (iv) | Where the fuel is, or may be, coal and there is no watertight bulkhead between the engines and the boilers, a direct discharge overboard or alternatively a bypass to the circulating pump discharge, shall be fitted from any circulating pump used in compliance with subparagraph (i) of this paragraph. |

(h)

| (i) | All pipes from the pumps which are required for draining cargo or machinery spaces shall be entirely distinct from pipes which may be used for filling or emptying spaces where water or oil is carried. |

| (ii) | All bilge pipes used in or under coal bunkers or fuel storage tanks or in boiler or machinery spaces, including spaces in which oil-settling tanks or oil fuel pumping units are situated, shall be of steel or other approved material. |

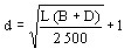

| (i) | The diameter of the bilge main shall be calculated according to the following formulae provided that the actual internal diameter of the bilge main may be of the nearest standard size acceptable to the Administration: |

![]()

where—

d = internal diameter of the bilge main in millimetres;

L and B are the length and the breadth of the ship in metres, as defined in Regulation 2 of this Chapter; and

D = moulded depth of the ship to bulkhead deck in metres; or

where—

d = internal diameter of the bilge main in inches;

L and B are the length and the breadth of the ship in feet, as defined in Regulation 2 of this Chapter; and

D = moulded depth of the ship to bulkhead deck in feet.

The diameter of the bilge branch pipes shall be determined by rules to be made by the Administration.

| (j) | The arrangement of the bilge and ballast pumping system shall be such as to prevent the possibility of water passing from the sea and from water ballast spaces into the cargo and machinery spaces, or from one compartment to another. Special provision shall be made to prevent any deep tank having bilge and ballast connections being inadvertently run up from the sea when containing cargo, or pumped out through a bilge pipe when containing water ballast. |

| (k) | Provision shall be made to prevent the compartment served by any bilge suction pipe being flooded in the event of the pipe being severed, or otherwise damaged by collision or grounding in any other compartment. For this purpose, where the pipe is at any part situated nearer the side of the ship than one-fifth the breadth of the ship (measured at right angles to the centre line at the level of the deepest subdivision load line), or in a duct keel, a non-return valve shall be fitted to the pipe in the compartment containing the open end. |

| (l) | All the distribution boxes, cocks and valves in connection with the bilge pumping arrangements shall be in position which are accessible at all times under ordinary circumstances. They shall be so arranged that, in the event of flooding, one of the bilge pumps may be operative on any compartment; in addition, damage to a pump or its pipe connecting to the bilge main outboard of a line drawn at one-fifth of the breadth of the ship shall not put the bilge system out of action. If there is only one system of pipes common to all the pumps, the necessary cocks or valves for controlling the bilge suctions must be capable of being operated from above the bulkhead deck. Where in addition to the main bilge pumping system an emergency bilge pumping system is provided, it shall be independent of the main system and so arranged that a pump is capable of operating on any compartment under flooding conditions; in that case only the cocks and valves necessary for the operation of the emergency system need be capable of being operated from above the bulkhead deck. |

| (m) | All cocks and valves mentioned in paragraph (l) of this Regulation which can be operated from above the bulkhead deck shall have their controls at their place of operation clearly marked and provided with means to indicate whether they are open or closed. |