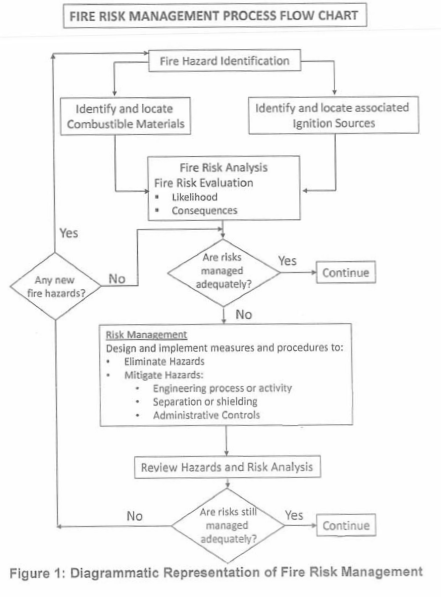

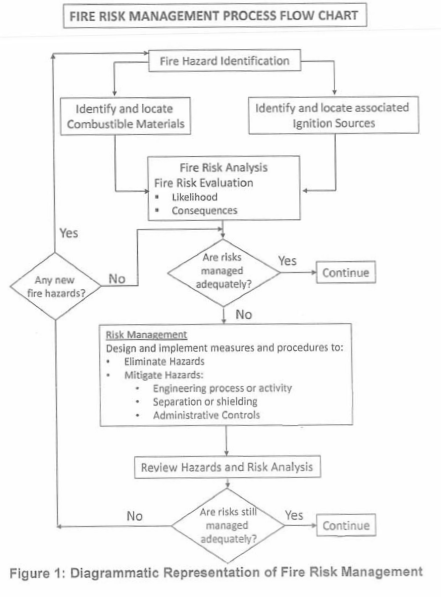

In order to manage the risks associated with fires at a mine, the COP should set out a structured Fire Risk Management Program covering at least the steps and measures envisaged in this guideline. Figure 1 below shows diagrammatcially the Fire Risk Management Program covered in this guideline.

| 8.1 | Fire and risk management |

The COP should set out as the first element of a Fire Risk Management Program the requirement to identify fire hazards and then fire risks. The COP should require these to be continuous activities covering the following:

| 8.1.1 | Identification of fire hazards |

The COP should identify each possible fire hazard and classify each as either a fuel source or an ignition source (under certain circumstances, timber, coal and other organic materials may be both). The location of all possible ignition sources, at fixed sites at a mine or on mobile or semi-mobile equipment operating at a mine should be established.

Fires will occur if these two sources are present simultaneously in time and space. Preventative measures may be put in place to prevent such interactions and, under certain conditions, suitable physical barriers may be introduced to prevent the two sources from interacting. These are classified as protective measures against fires. Other actions and procedures, such as emergency evacuation procedures and the use of refuge bays, for example, are seen as measures needed to mitigate the impact following from the ignition of combustible material to protect workers. This COP shall concentrate predominantly on preventative measures and on some protective measures aimed particularly at separating effectively the two sources.

Annexure 1 Generic notes on fires provides more information on the stages of fire, covering the nature and development thereof.

| 8.1.1.1 | Fire hazards: Fuel sources |

The COP should classify the identified fuel sources in terms of the fire classes defined by the combustion process associated with them:

| (a) | Class A: Materials (ordinary combustibles) |

These are solid materials, usually of an organic nature, in which combustion normally results in the formation of glowing embers. These include combustibles such as wood, paper, fabric, plastics, and most kinds of solid waste materials.

| (b) | Class B: Materials (flammable liquids and gases) |

These are non-solid fuels consisting of flammable or combustible liquids or gases such as petrol or propane gas.

| (c) | Class C: Energized electrical equipment |

Electrical fires involve potentially energised electrical equipment. This sort of fire may be caused by short- circuiting or overloaded electrical networks.

| (d) | Class D: Combustible metals |

Combustible metals mostly encountered are magnesium, potassium, titanium, and zirconium. With the exception of the metals that burn in contact with air or water (for example potassium and sodium), combustible metals on their own do not represent unusual fire risks because they have the ability to conduct heat away from hot spots efficiently. However, when combustion is induced, the fire is self-sustaining: rapid combustion (oxidation) of magnesium induced by an external source may result in a fiercely exothermic process.

| (e) | Class F: Cooking oils and fats (kitchen fires) |

These include unsaturated cooking oils in well-insulated cooking appliances located in commercial kitchens. Though such fires are technically a subclass of the flammable liquid/gas category, the special characteristics of these types of fires, namely the lower flash point, are considered important enough to re classify these separately. Water mist can be used to extinguish such fires.

| 8.1.1.2 | Fire hazards: Ignition sources |

The COP should identify potential sources of ignition at a mine including but not limited to the following energy sources:

The presence of heat energy is often characterised by high temperature surfaces (e.g. exhaust systems of internal combustion engines, pumps, turbochargers, electric motors, gearboxes, heat exchangers, bearings, rubbing surfaces such as brakes, cigarette butts, naked flames from use of welding equipment and matches or cigarette lighters).

Switch gear, motors, retarders, transformers, lights and cables; short-circuit arcs, earth-faults, static electricity discharge, induction heating, thyrist or drives.

Friction (conveyor belts drives, winch ropes), mechanical impact (coal picks) or grinding.

Self-heating, auto-ignition, exothermic reactions, of coal and induced spontaneous combustion of coal and induced pyrolysis of vehicle tyres (lightning).

| 8.1.1.3 | Fire hazard identification process |

The COP should set out the Fire hazard identification process that requires a physical inspection of all working places, of travelling ways, hoisting and conveying infrastructures and of equipment and machinery used at a mine to identify and list all recognisable fuel and ignition sources. In addition, the fire hazard identification process shall include a review of processes employed at a mine to assess the probability of a fire being caused as the result of operational malfunctions or of process design failures.

The outcomes of the fire hazard identification process should be recorded in a Fire hazard register that identifies the hazard together with its classification (fuel source, ignition source or both) and location of the hazard at the mine. The latter should distinguish whether the fire hazard is fixed or mobile, as might be the case for vehicles. The location of fixed hazards should be deemed to be particularly hazardous where these are located in or in close proximity to intake airways, at sites containing other fire hazards (e.g. transformer station adjacent to fuel storage areas) or sites that might be adversely affected directly or indirectly by a fire (e.g. major oil-filled transformers adjacent to sub-vertical shafts or sub-declines or other fresh air intakes). The latter is of particular importance where mobile equipment is operated.

A series of different fire hazard identification processes may be undertaken at different stages in the life of any mining project. These should be appropriate in terms of and aligned with the maturity of the operation and of changes that take place from time to time due to process or system design modifications, introduction of new technologies and/or equipment and as a result of changes in accepted practices.

| (i) | Baseline and issue-based fire hazard surveys |

The COP should set out baseline and issue based procedures that are summarised in the fire hazard register and to include the following information:

| (a) | The date of the survey; |

| (b) | The name of the person responsible for the respective assessments: |

| (c) | A list of operational procedures and standards that were affected (added, amended or deleted) as the result of such assessments; and |

| (d) | The details of where the official risk assessment documentation is kept at the mine. |

These surveys should be completed as soon as any type of mining operation is undertaken (e.g. shaft sinking, primary development, plant construction, production ramp-up, etc.) and whenever a major change or addition to the operation or process is undertaken (e.g. sinking of another shaft or subvertical structure, extension of the mineral treatment plant, etc.)

Additionally, a review of the baseline risk survey should be conducted with the occurrence of changes in conditions and/or processes or resulting from an incident. The information from the risk survey can then be (used as a basis for the assessment and control of fire risk (refer to section 8.1.2: Assessment of fire risks).

| (ii) | Continuous fire hazard identification |

The COP should set out measures ensuring that in the event of any changes in the equipment operated, systems or processes employed as recorded in section i) above, additional surveys should be performed to supplement the baseline fire hazard survey. In the absence of these changes, the baseline fire hazard surveys should be reviewed at intervals not exceeding 12 months. These reviews could include, but are not limited to, items identified during:

| (a) | Employee fire hazard identification and reporting procedures; |

| (b) | Workplace inspections and observations; and |

| (c) | Equipment and plant inspections. |

The COP should include a record of any instances where operational standards and procedures have been amended following such reviews.

Refer to Annexure 2: Examples of fire hazards at mines.

| 8.1.2 | Assessment of fire risks |

| 8.1.2.1 | Fire risk assessment method |

The COP should ensure that all identified fire hazards are analysed to assess their contribution to the overall fire risk. In the assessment of fire risks, the following should be included:

| (a) | The identified fuel and potential ignition sources and other factors that can have an impact on the type and magnitude of the risk; |

| (b) | The evaluation of the fire risk based on the assessed consequence and likelihood of a particular fire event; and |

| (c) | The input from a number of specialist areas, including occupational hygiene/mine ventilation and emergency response as part of the risk mitigation process. |

Where appropriate, similar fire hazards or classes of fire hazards may be analysed in logical groupings as might be determined by the mine's infrastructure, process or design.

| 8.1.2.2 | Fire risk assessment tools |

The COP should outline measures to ensure that the selected risk assessment tools should be applicable for the intended function and should provide effective indication of:

| (a) | The actual risk as understood at the time; |

| (b) | Any intervention deemed to be feasibly effective in reducing such risk (preventative measures); |

| (c) | The effect of any corrective interventions (preventative measures) being considered; |

| (d) | The impact of any residual risk after the application of the preventative measures; |

| (e) | Any (further) protective measures that might be considered to manage any residual risk, (e.g. including fire detection and fire-fighting measures); and |

| (f) | Monitoring criteria that will determine the effectiveness of anticipated or implemented risk reduction controls. |

The assessment of the fire risks should take into consideration impacts and consequences of any fire incident on the health and safety of workers, on neighbouring communities, on the environment and the on future viability of operations (e.g. material and reputational damage).

Any mitigating preventative and/or protective measures proposed for identified fire risks, should be recorded formally to an adequate level of detail, should be approved by management and be assigned to competent persons for completion within a specified period of time consistent with the level of the identified risk rating assigned to the corresponding fire hazard.

The COP should ensure that the risk analysis section includes information on the type and nature of fire hazards and any contributing operational and environmental factors for consideration in the structuring of adequate preventative and protective measures. Risk analyses should focus on the following but should not be limited to:

The COP should ensure that the potential for fires at a mine is determined using the fire hazard identification process described in section 8.1.2 above. Where specialised processes are undertaken, the assistance of recognised experts in the field of fire engineering should be sought.

| (ii) | Characterising potential fires |

Once the fuel and ignition sources have been identified, the fire risk should be characterised for each using information such as:

| (a) | The quantity of fuel available for combustion; |

| (b) | "Fuel loading "or the relative mass of the fuel (or potential calorific energy) per unit volume of the occupied space (high, moderate or low fuel loading); |

| (c) | The chemical composition and intensity of smoke and fumes or gases likely to be generated by a fire (this information should be used for the selection of a suitable emergency evacuation procedure); |

| (d) | The location of fuel and combustible material storage areas, relative to other areas; |

| (e) | The route that will be followed by any smoke generated by a fire (to define possible escape routes); and |

| (f) | The presence of further fuel sources that might participate in an extended fire scenario. |

| (iii) | Fire hazard location |

The location of a fire hazard could have a significant impact on the level of risk:

| (a) | Fires located in a main intake airway (e.g. main decline) are likely to pose a higher risk than if located in a return airway; |

| (b) | Fires located close to the main working areas are likely to provide less time for affected personnel to respond timely and adequately (i.e. there will be limited time for employees to evacuate to a place of safety such as fresh air bases and refuge bays); |

| (c) | Fires on surface close to fresh air or compressed air intakes to underground workings or to offices on surface can pose a significant risk; and |

| (d) | Fires located close to or within, hazardous material and combustible liquids storage enclosures have the potential to pose a risk to other neighbouring areas. |

| 8.1.2.4 | Risk assessment output |

The COP should ensure that the fire risk assessments shall yield the following information that shall not be limited to:

| (a) | locations throughout the mine where fuel and ignition sources exist; |

| (b) | types and extent of fire events considered; |

| (c) | consequence and likelihood of each fire event; |

| (d) | the resulting fire risk (e.g. based on a consequence and likelihood risk matrix); |

| (e) | controls and associated monitoring criteria currently in use to minimise the risk; |

| (f) | any additional actions to further reduce risk by either improving existing controls or by providing additional controls or actions (included in authorised work programs and assigned to a competent person for completion); and |

| (g) | any additional actions aimed at mitigating or reducing the impact of the outcome; |

Note: The composition and quantity of smoke and fumes generated in a fire are likely to have a significant impact on the consequence of the fire and hence the level of risk The impact of heat generated by an incipient fire should also be considered as a small fire in a "critical" location may provide sufficient heat to initiate a much larger conflagration.

| 8.2 | Fire prevention controls |

In this section of the COP, the application of adequate controls for mines is described by considering fire prevention at the systems, processes and equipment employed at the mine. A control is an action aimed primarily at preventing the occurrence of a fire incident or an intervention intended to limit the impact of any incipient fire. These can take the form of a process or equipment re-design, implementation of different material selection criteria or of adequate operational standards.

Controls shall be assigned to each fire hazard and corresponding risks identified and defined in the fire risk management section. The number and degree of coverage of controls shall be commensurate with the level of anticipated risk.

All fire prevention controls should be listed in the COP and must be aligned with the findings of the various fire risk assessments. To this end, the COP should include a register listing all fire prevention controls (in place or planned) including risk based monitoring criteria together with the reference risk assessment document to which they are linked.

Critical controls are actions or interventions whose integrity will ensure that the hazard will not cause harm and should be recognised as such in the controls register. Monitoring criteria for the effectiveness of critical controls should be employed. Regular monitoring and recording of the performance of defined critical controls should take place.

The following section provides broad parameters applicable to relevant fire prevention controls. The COP should provide the objectives of each major control under the headings provided below. To provide the necessary guidance, reference should be made to the support notes provided at the end of this guideline

| 8.2.1 | Design, construction and operation |

The COP should ensure that the design, construction and operation of any process or system employed at any mine conforms to regulated standards and design codes in compliance with the MHSA. In addition, the design, construction and installation of any equipment and machinery in use at mines must comply with national standards, applicable design codes and section 21 of the MHSA.

Inherent with this, is the requirement that systems, processes and equipment shall be designed, constructed and installed, so as to prevent or avoid contribution to the occurrence of fires under normal operations.

Annexure 4 General Design Requirements Mobile Equipment and Annexure 5 General Design Requirements for Fuel Storage Areas, Fuel Transfer Equipment and Refuelling Bays provides principles against which design, construction and operational parameters may be assessed in relation to fire hazards for inclusion in the COP.

| 8.2.2 | Mine infrastructure |

The COP should identify fire hazards and record in the fire hazard register infrastructure and installations all that could pose a significant fire risk such as, but not limited to:

| (a) | Fuel storage and associated r er equipment; |

| (c) | Main substations and switchgear installations; |

| (d) | Underground hoisting stations; |

| (f) | Densely timbered areas in intake airways; |

| (g) | Diesel fuel lines in main shafts and declines - where these are used for transport; |

| (h) | Any fire hazardous areas as classifiable by SANS 10108: Fire hazardous area classification; |

| (i) | High density surface storage area, e.g. fire hazardous material and combustible liquid storage areas, timber yards, fuel storage tanks, liquid oxygen tanks, ammonia refrigeration plants, etc; and |

| (j) | Waste disposal containers. |

To minimise fire risk at critical installations and infrastructures, the following requirements should be considered at the design stage:

| (a) | The installation of infrastructure that could pose a heightened high fire risk should only be undertaken following a formal assessment and consideration of the controls necessary to minimise risk; and |

| (b) | Wherever possible, such high risk infrastructures should be located in the return airways or near these, to facilitate exhausting of smoke and gases directly to return in the event of a fire and/or be equipped with suitably designed fire doors that would shut-off in the event of a fire thereby limiting or reducing smoke contamination of fresh air streams. |

The COP should address the following list of fixed plant components that should be assessed as part of fire hazard identification audits. This list provides some guidance which is neither complete nor exhaustive:

| (a) | Air, gas or refrigerant compressors; |

| (b) | Major electrical installations: |

| (c) | Crushers (surface and underground); |

| (d) | Mineral processing plants, inclusive of smelting and refinement processes; |

| (e) | conveyor belt installation (underground and surface); |

| (f) | Hoist rooms and winding plant installations(surface and underground); |

| (i) | Shaft sinking equipment; |

| (j) | Materials handling equipment: and |

| (k) | Fire hazardous material and combustible liquid storage areas. |

Annexure 3: Mine infrastructure and fixed plant provides examples of preventative controls that should be considered underground and on surface for fixed plant components as classified in SANS 10108: Fire hazardous area classification.

The location of fixed plant equipment in underground and confined spaces should consider the normal flow of fresh air so as to guide the type, size and location of any fire detection and fire-fighting equipment.

All fixed electrical and related equipment such as sub-stations, switch-rooms and main distribution boards should be in accordance with applicable SANS standards (such as, but not limited to, SANS 60076 (2011): Power transformers, SANS 1029 (2008): Mini substations, SANS 62135 (2013): Resistance welding equipment and SANS 10280 (2013) - Overhead power lines for conditions prevailing in South Africa and:

(a) Be designed constructed and installed in accordance with the manufacturer's standard;

| (b) | Be equipped with at least over-current, earth leakage and short circuit protection; |

| (c) | Be designed and constructed so that oil leaking from transformers and switchgear installations is contained; and |

| (d) | Consider the use of "dry", "inert gas" or emulsified (low flammability) coolant options for transformer and switchgear equipment. |

Fire prevention measures and protection equipment considered for these installations shall be designed to address adequately and reasonably the level of fire risk.

Where flammable oil is used, fixed electrical equipment should:

| (a) | Be provided with automatic fire suppression systems; |

| (b) | Be located so that the air current that flows over them passes direct to return; and |

| (c) | Have aggregate bund walls capable of containing the total oil volume with a plus 10% excess to capture any oil spillage. |

The COP shall include details of any fire detection systems installed following the respective fire risk assessment action plan as well as of any fire-fighting equipment provided as a further protective measure. This specialised equipment should be designed, installed and maintained in association with competent fire engineering experts.

The COP should reference the design and operation of workshops both on surface and underground. The following aspects should be included in workshop standards and operating procedures:

| (a) | Workshops should contain a minimum storage of combustible liquids (oils, lubricants, fuel, etc.). Storage quantities shall not exceed consumption for one week's work; |

| (b) | Any combustible liquids should be stored in segregated locations; and |

| (c) | Appropriate signs as per SANS1186-1 (2011): Symbolic safety signs - Part 1: standard signs and general requirement, and notification should be installed at all entrances to workshops indicating: |

| • | Type and volume of combustible liquids stored; |

| • | No smoking or naked lights near flammables; |

| • | Hot work in designated areas only; |

| • | Housekeeping requirements; and |

| • | Emergency procedure in case of fire. |

| (d) | The maximum mass of combustible materials stored or in use in a workshop in different subdivisions shall not exceed one week consumption (e.g. fuel, lubricants, grease, rubber or poly-urethane filled tyres, paints, welding gas cylinders, etc.). This information should be used to determine the appropriate type and quantity of fire-fighting equipment as well as the location of any fire detection sensors. |

| (e) | The design of the ventilation system serving workshops must follow a risk-based approach that caters for: |

| • | Position of machinery, equipment, temporarily stored material (consumables) vehicles being serviced at any one time (e.g. diesel emissions, hydrogen liberated during battery charging, etc.) and the workshop volume taken-up by these under normal and exceptional circumstances. These will all affect air-flow patterns in the workshop, response of any smoke sensing equipment and effectiveness of any fixed fire suppression equipment; |

| • | Positioning of the workshop in relation to intake and return airways. This is important to determine the strategy to be adopted in the event of a fire and the type of fire detection and fire-fighting tactic; and |

| • | Contingency arrangements may be required in the event of power failures. |

| (f) | Where part of a workshop is earmarked for hot work (welding, grinding, cutting or heating or burning using oxy-acetylene or electric welding), separate locations (cutting bays or welding bays or grinding bays) should be provided and supplied with adequate flow of fresh air to dilute any smoke or fumes generated by such work. Standard operating procedures should reflect a blanket permission to allow hot work whenever this is performed in these locations. |

| (g) | Hot work permit systems must be implemented for hot work in any other area of the mine. |

| (h) | Chemicals in stores that can generate heat or release fumes should be appropriately separated from workshops working areas. |

| (i) | Sealed waste oil disposal system and suitable containers for the disposal of other flammable waste should be used to minimise spillage. |

| (j) | Space heaters should not be used in workshops unless they have a surface temperature less than 300 °C and are kept clear of rags, paper and other flammable material. |

| (k) | Welding gases such as acetylene and oxygen should be stored and used in accordance with OEM requirements. |

| (l) | Workshops should be provided with adequate spillage containment facilities (e.g. water hose, absorbent material) to contain or clean-up any fuel spills quickly and effectively. |

| (m) | Any waste (e.g. soiled absorbent material) should be placed immediately in clearly marked receptacles and be kept well away from any potential ignition source these receptacles should be emptied at least weekly. |

| (n) | Fire extinguishers and fire-fighting equipment should be installed as required. |

| (o) | Suitable barriers or designated parking areas should be installed to provide for adequate separation of mobile equipment from flammable materials. |

| (p) | The following SANS standards should be considered during workshop design: SANS 10400(2009): National building regulations, SANS 10263(2009): The warehousing of dangerous goods and SANS 10232(2007): The transport of dangerous goods. |

The COP should address the risk posed by the operation of self-propelled mobile equipment at a mine or in a confined environment (e.g. a surface coal bunker) as determined by a number of factors such as:

| (a) | The mass of flammable material on the vehicle. This may include, but is not limited to: |

| • | The nature of the payload (more fuel, oil, timber, etc.). |

| (b) | The routing (mobility) of the vehicles particularly in main intake airways - as a vehicle fire is likely to contaminate the air downstream of the event. |

| (c) | Propensity of a vehicle fire to involve other parts of the mine (e.g. coal seam in coal mines, plastic piping in roadways, timber support in drives, etc.). |

| (d) | The location of refuelling bays or places where (temporary) maintenance is done. |

| (e) | The air quantity flowing past a potential fire site and sites through which is coursed downstream. |

The general design of vehicles should conform to minimum SANS 868: Compression (ignitions engine system and machines powered by such engine system, for use in mines with explosive gas) and plants as applicable or manufacturer's specification. The routing of electrical (power) cables, fuel and hydraulic lines, particularly in engine bays, near brakes and pinch-points should be such that incidental damage and contact with hot surfaces is avoided. Pipes and hoses should be manufactured from high quality; durable materials and the piping layout should consider abrasive action and allow for adequate mobility.

The integrity of the original manufacturer's design as accepted by the mine and in line with this COP, amongst others, should be maintained for the life of the equipment.

Annexure 4 General Design Requirements Mobile Equipment provides series technical solutions risks posed by the operation of self-propelled mobile equipment.

Annexure 6 Safe Use, Transport and Handling of Explosives provides examples of preventative controls that should be considered underground and on surface for the transport of explosives (Referencing to the explosive procedure in terms of MHSA regulation 4.2(b).

8.2.6 Managing fire potential

The COP must indicate measures to address the storage and use of such substances or materials that have a flash point below 60°C, including compressed gases such as acetylene and propane. The use and presence of flammable substances at a mine is inevitable and therefore the risk posed by these must be managed adequately. The relevant SDSs in accordance with SANS 10234 (2008): List of global harmonised classification and labelling of chemicals must be consulted to determine the type of any precautionary measures that require implementation.

| 8.2.6.1 | General requirements |

The COP should set out measures to minimise fire risk associated with the storage or use of flammable substances at the design or selection stage. The following should be considered:

| (a) | Wherever possible and reasonable, flame retardant materials should be used in preference to flammable materials; |

| (b) | All combustible materials should be stored in dedicated, clearly-marked storage areas; |

| (c) | The use and location of flammable substance storage areas should only be undertaken following a formal assessment and consideration of the controls necessary to minimise risk; |

| (d) | Wherever possible and reasonable, flammable substance storage areas should be ventilated into the return airways or have suitable fire doors installed to limit smoke ingress into working areas and intake airways. Flammable substance storage equipment should be constructed of non-flammable materials; |

| (e) | No Smoking' and No Naked Flame' signs should be displayed at all flammable materials storage locations; |

| (f) | Flammable materials should not be stored on or near heat or ignition sources: |

| (g) | The routing of electrical cable clusters, particularly high tension lines, should not be allowed within close proximity from flammable materials. Each application shall be considered on merits dictated by risk considerations, good practice and the use, where necessary, of adequate protective (shielding separating) measures; or |

| (h) | Electrical switchboards should not be placed in flammable material stores; |

| (i) | Wherever possible and reasonable, light fittings should be mounted clear of flammable materials; |

| (j) | All electrical equipment should meet relevant electrical standards for design and installation and should be used as intended by the manufacturer; |

| (k) | Where necessary and as indicated by an assessment of the risk, smoke alarms and earth leakage protection should be installed on electrical equipment that is left to operate unattended; |

| (l) | The quantity of flammable materials stored in any location, should be kept to a minimum as per mine risk assessment; |

| (m) | Flammable material storage equipment should be located away from high traffic or collision-prone areas or be otherwise protected against vehicle collisions; |

| (n) | Wherever possible and reasonable, hot work should not be done in or near flammable materials, in the presence of flammable gases or other such fluids. A permit system for hot work (inclusive of adequate preventative and protective measures) should be in place for any such work outside workshops; and |

| (o) | Wherever possible and reasonable, vehicle access to combustible stores should only be for the purpose of loading and unloading. Vehicles should not be parked in tyre stores. |

8.2.6.2 Combustible substances

The COP should address measures for the storage and use of combustible substances or materials at mines that generally have a flash point below 60°C. This includes Class 3 flammable liquids.

Foams and resins may be particularly volatile in their component form (i.e. prior to mixing). Where foams are used they must comply with SANS 1867 (2003): Sprayed plastic foams for use in mines.

The COP should address the following requirements related to the use and storage of flammable solid materials:

| (i) | Where the large-scale use of timber support is necessary, the COP should make reference to a programme to identify densely timbered areas, particularly in intake airways and storage areas. The choice of any specific mitigating measure such as, for example, impregnating timber with fire retardant chemicals or coating of exposed timber with inert (intumescent) material, should be risk-based and specified accordingly in operating procedures. |

| (ii) | The COP should outline any special measures for the prevention of fires in waste storage facilities. These could include, but not limited to: |

| • | Adequate ventilation measures for some waste storage facilities; |

| • | Displaying 'No Smoking' signs in the waste storage facilities and near refuse containers; |

| • | The regular removal of waste materials from refuse containers and waste storage facilities at adequate intervals to prevent the accumulation or overflow of waste materials. |

The use, transport and handling of explosives in mines may be considered to be an additional fire hazard. This COP should make reference to the relevant standards procedures and precautionary measures intended for the safe use, transport and handling of explosives used at a mine.

The COP should reflect the following requirements related to the use and storage of flammable liquids:

| (i) | All vessels containing flammable liquids should be provided with clear and easily understood labels and respective SDSs; |

| (ii) | Only purpose-built containers, designed to prevent spillage, should be used to transport flammable liquids. Diesel fuel should only be transported in purpose-designed bowers or jerry-cans, adequately secured to the vehicle's loading tub; |

| (iii) | Where large quantities of flammable fuels are stored, e.g. diesel fuel storage tanks, oil cooled transformers, etc., and where justified by risk-based considerations, storage vessels should be enclosed in a containment area (bund wall) where any spillage following the rupture of the containment vessel. The containment area should be large enough to accommodate 110% of the maximum flammable liquid volume in storage at any time. In addition, if this area should be filled with inert material such as gravel consideration must be taken into the volume of flammable in the storage vessel. If liquid any drainage system is used it must be fitted with a device that is normally closed; and |

| (iv) | The vehicles fled for the transport of flammable liquids should be appropriately designed for the task. |

Annexure 5: General design requirements fuel storage areas, fuel transfer equipment and refuelling bays below includes reference to a number of items relating to fuel storage areas, fuel transfer equipment and refuelling bays for possible consideration in structuring standards supporting the management of fire risks associated with these.

Annexure 6: Safe use, transport and handling of explosives below provides suggestions that might be included in procedures for the safe transport handling and use of explosives. These are provided for possible reference and inclusion in operating procedures.

The management of risks associated with the natural occurrence of flammable gases in underground operations, i.e. resulting from mining operations, is not included in this COP. Reference should be made, however, to the respective COPs for the prevention of flammable gas explosions. This COP is to address the use of industrially manufactured flammable gases that may be used in various processes at a mine, mainly welding.

The COP should reflect the following requirements related to the use and storage of flammable gases used in "hot work ":

| (i) | Flammable gas cylinders should be stored in a well-ventilated area; |

| (ii) | Flammable gas cylinders should be transported and stored in accordance with the relevant manufacturer's specification; |

| (iii) | Gas cylinders should be secured so that they cannot fall over. In particular, cylinders containing acetylene should always be stored in an upright position; |

| (iv) | When transporting cylinders, they should not protrude over the vehicle's loading bed extremities; |

| (v) | Flash-back arresters should be installed on all oxy-acetylene equipment: |

| (vi) | The contents of flammable gas cylinders should not be decanted; and |

| (vii) | Oxy-acetylene equipment should only be used in accordance with accepted operational standards and only in designated "hot work areas" or when approved through the use of a "hot work permit". |

| 8.2.6.3 | Operating and maintenance procedures |

The COP should reflect the following:

| (a) | Operating procedures should be developed from the action plans drawn from the various fire risk assessments. |

| (b) | Maintenance systems should be in place to ensure that all equipment, both mobile and fixed plant, is maintained properly and according to the manufacturers' recommendations and that any defects are recorded and promptly repaired. |

| (c) | Oversight procedures are in place to ensure that: |

| ✓ | Regular maintenance of equipment for the prevention of fires, used for fire detection and fire-fighting is essential in the implementation of the various protection measures; |

| ✓ | All repair and maintenance activities for machinery, systems and equipment associated with fire risks and employed for fire prevention and protective measures should be carried out at specified intervals, by suitably qualified individuals and in accordance with original equipment manufacturer specification; |

| ✓ | Repair and maintenance activities must restore equipment to the intended design and operational functionality; and |

| ✓ | Employees training programmes for fire prevention procedures and awareness should be aligned with requirements and findings of the various fire risk assessments to ensure adequate levels of proficiency and effectiveness and acceptable workmanship. |

Annexure 7: Generic operational and maintenance procedures below provides suggestions that might be included in procedures for generic operational and maintenance procedures. These are provided for possible reference and inclusion in operating procedures.

| 8.3 | Purchasing procedures |

The COP should include the requirement that the mine's purchasing procedures be developed and implemented to ensure that any machinery, equipment or materials purchased for use at the mine comply with site standards. This procedure should:

| (a) | Require manufacturers or suppliers to provide evidence that fire risks associated with such machinery, equipment or materials have been considered and addressed (refer Section 21 of the MHSA) and in compliance with applicable at least national standards: |

| (b) | Require manufacturers or suppliers to make mine management aware of any residual fire risk, either patent or potential that might be associated with the use of such machinery, equipment or materials; |

| (c) | Require manufacturers or suppliers of machinery to advise mine management of any fire-fighting equipment or additional fire protection requirements associated with the use of such machinery at a mine; |

| (d) | Ensure that SDS's are provided for any combustible or flammable materials supplied to the mine; |

| (e) | Require that manufacturers or suppliers of machinery or equipment provide adequate information on the operational procedures and maintenance requirements, particularly relating to any specific fire-detection or fire-fighting equipment custom built into the machinery. Alternatively, requirements and specifications for such fire-detection or fire-fighting equipment that might have to be provided separately by a third party need to be communicated adequately; |

| (f) | Require that manufacturers or suppliers of machinery or equipment provide adequate training and /or training material to ensure the proficiency of machinery or equipment operators; and |

| (g) | Ensure that machinery and equipment specifications and maintenance and operational manuals are included in tender documents for any new contracts. |

The COP should reflect the requirements stated in Regulation 5.1 of the MHSA, in particular that:

"The employer must ensure that a competent person reports to the employer, at appropriate intervals determined in accordance with the mine's risk assessment, on—

| (a) | The effectiveness of the precautionary measures taken to prevent or suppress explosions of coal dust or flammable gas; and |

| (b) | The adequacy of measures in place to prevent, detect and combat the start and spread of mine fires." |

The COP should include the requirement that a series of inspections relating directly to fire hazards be performed as follows:

| (a) | Fire hazard audits: Intervals are to be stipulated in accordance with section 8.1.1 of this guideline; |

| (b) | Regular inspections of working areas to monitor compliance with fire controls, including preventative procedures and fire protection equipment; and |

| (c) | Inspections aimed at identifying either substandard acts or work practices (behaviour) and substandard conditions (fire hazards). There are usually two types of inspections: |

| • | Formal inspections of all workplaces that are undertaken on a regular (i.e. weekly or monthly) basis, depending on the level of risk (e.g. weekly explosives magazine inspections). Formal inspections generally involve the use of area-specific or task specific check-lists to record any defects; and |

| • | Informal inspections that are undertaken by employees, supervisors and managers on a daily basis. |

Formal inspections must be recorded in adequately structured, fit-for-purpose reports. Any observed defects or deviations or irregularities are to be reported immediately verbally and then in writing to the legally appointed person - irrespective of the type or level of inspection being carried-out.

Annexure 8: Inspections provides guidance for consideration during inspections.

| 8.5 | Awareness training for fire prevention |

In all documents relating to training in elementary fire-fighting procedures, caution should be exercised so as to prevent employees from being exposed to danger during fire-fighting operations. It is recognised that the dousing of an incipient fire is an effective measure to limit the impact of any such incident. However, employees must be warned of the dangers of going beyond their level of knowledge and proficiency in using fire-fighting equipment.

The COP should set out measures to address awareness training under the following sub-headings:

| 8.5.1 | General fire prevention awareness |

Basic fire prevention awareness training should be provided as part of the mine induction.

Refresher training should then be conducted every 12 months as part of regular safety/tool-box meetings.

All personnel who work at the mine should have a basic understanding of fire prevention measures and be trained and assessed for competency in:

(a) Basic fire theory;

| (b) | Basic fire prevention methods; |

| (c) | Understanding of fire potential risks; |

| (d) | Use of the first response of basic fire-fighting equipment, including portable extinguishers, installed on-board vehicle fire suppression systems, etc; |

| (e) | Behaviour of fire in enclosed environments, including the role played by ventilation systems; |

| (f) | Emergency procedures, including use of self-rescuers, refuge chambers and emergency assembly points; |

| (g) | Reporting procedures during fire emergencies; and |

| (h) | Distinguishing and identifying audio and visual fire alarms where provided. |

| 8.5.2 | Mobile equipment operators training |

In addition to the general fire awareness training, all operators of mobile equipment at the mine should be trained and assessed for competency, with the assistance of equipment manufacturers or suppliers where necessary, in the following preventative and precautionary measures:

(a) The basics of conducting proper inspections;

| (b) | Identification of overheating surfaces; |

| (c) | Requirements for minimising engine and equipment temperatures through correct operating technique; |

| (d) | Procedures to isolate on-board electrical power sources safely; |

| (e) | Electrical fire hazards; |

| (f) | Use of refuelling equipment and refuelling procedures; |

| (g) | Fire prevention measures of tyre fires; and |

| (h) | Response to any fire that may occur on a vehicle based on the equipment available. |

| 8.5.3 | Fixed plant operators training |

All personnel who operate fixed plant at the mine should be trained and assessed for competency, with the assistance of equipment manufacturers or suppliers where necessary, in the following preventative and precautionary measures:

| (a) | Identification of overheating surfaces; |

| (b) | Requirements of machinery or equipment electrical isolation also in accordance with regulatory provisions; |

| (c) | Equipment operational condition monitoring (e.g. normal operating temperatures, pressures and response to changing conditions); |

| (d) | Recognising mechanical and electrical fire hazards; and |

| (e) | Where appropriate, safe emergency stopping of machinery using brakes in terms of regulatory provisions. |

| 8.5.4 | Mobile equipment maintenance awareness |

All personnel involved in the maintenance of mobile equipment at the mine should be trained and assessed for competency, with the assistance of equipment manufacturers or suppliers where necessary, in the following preventative and precautionary measures:

| (a) | Use of the maintenance system check sheets; |

| (b) | Equipment pre- and post-maintenance inspections; |

| (c) | Equipment operational condition monitoring (e.g. normal operating temperatures, pressures and response to changing conditions); |

| (d) | Inspecting and checking of "V" belts, rigid and flexible guards and hoses; |

| (e) | Installation and replacement of hydraulic and pneumatic hoses for specific equipment; this should also include the correct use of hose crimping, where required; |

| (f) | Use of hot work permits and welding equipment, where required; |

| (g) | Maintenance of fire suppression systems, where provided and necessary; and |

| (h) | Importance of completing pre-use checklist items pertaining to fire prevention measures. |

| 8.5.5 | Electrical maintenance personnel |

Personnel involved in the maintenance of electrical equipment or installations at the mine should be trained and assessed for competency with the assistance of equipment manufacturers or suppliers where necessary, in the following preventative and precautionary measures:

| (a) | Conducting thermal imaging and electrical tests; |

| (b) | Hot work permits system requirements; and |

| (c) | Live testing of equipment in line with procedures and legislated regulations. |

All personnel who undertake such work should also be appointed electricians qualified to work on the type of equipment (e.g. low voltage, high voltage, instrumentation, etc.).

| 8.5.6 | Fuel storage operational personnel |

Personnel involved in the transport, storage or handling of fuel, combustible materials and explosives at the mine should be trained and assessed for competency in at least but not limited to the following:

(a) Transport and storage procedures relating to fuel, combustible materials or explosives;

| (b) | Use of specialised distribution or unloading equipment; |

| (c) | Procedures for the refuelling of vehicles conveying these materials; |

| (d) | Access procedures to combustible material stores or explosives magazines; |

| (e) | Isolation of equipment prior to maintenance; |

| (f) | Emergency procedures specific to fuel facilities, combustible materials or explosives storage area; and |

| (g) | Personnel responsible for the receipt of bulk diesel, shall be specifically trained in the receipt of dangerous goods, and be "nominated" as the "qualified person ", referred to in SANS 10231(2010): Transport and dangerous goods. |

| 8.6 | Fire protection and emergency response |

The COP should reference broadly the mine's fire-protection and emergency response tactics for major fire hazards. In particular, this COP should describe the principles used in the selection of each tactic, the alignment of this with the respective fire risk assessment and any specialist input made in devising the protective measures and responses (e.g. fire engineering criteria to determine fire-fighting equipment specifications where deemed necessary, etc.).

Under this section, the COP should list and describe briefly the measures implemented for early detection of fires at different locations on the mine based list of fire hazard locations referenced in section 8.1.

Fire prevention measures as intended in this COP is a proactive endeavour aimed at eliminating the hazard of fire and should therefore be considered as the primary form of control. Fire protection is a secondary control aimed at reducing the consequences of a fire by limiting the severity and impact of a fire. Therefore, this guideline should be used in conjunction with the Guideline for emergency preparedness and response to provide a comprehensive and coordinated approach in addressing the fire prevention measures and control of fires.

Note: Under no circumstances should fire braziers (mbaula), i.e. any fixed or portable solid fuel or gas fired equipment or appliance designed for heating and used outdoors, be used at the mines.

| 8.7 | Effective means of monitoring and communicating the possible presence of a fire |

The COP should set out measures to monitor and communicate the possible presence of fire. This system should include the following:

| 8.7.1 | A brief description of the method(s) employed to detect the occurrence of a fire, presence of noxious gasses or flammable gasses underground; |

| 8.7.2 | A brief description of the approach used to position the sensors to monitor the air flow in the underground workings effectively for detecting the presence of a fire and facilitate its location in the mine; |

| 8.7.3 | A description of the channels of communication that are to be used after a fire has been detected, including communication with neighbouring mines where secondary outlets /escape routes are shared; |

| 8.7.4 | The process for monitoring of underground environmental conditions during a fire; and |

| 8.7.5 | A list of evacuation plans available in the control room that would include the following amongst others: |

| • | Location of various sensors; |

| • | Location of refuge bays (inclusive of telephone numbers); and |

| • | Identification of escape routes. |